Inside the CubeSat Connector

Our First PC/104 Pinout

In our last article, we introduced the PC/104 standard as one of the key building blocks behind CubeSat design. Now, we’re taking a deeper dive into it. The connector may look simple, but it plays a central role in how subsystems inside a satellite power up, communicate, and work together as a system.

When you think about a CubeSat, you often picture the aluminum frame, the solar panels, or maybe even the antennas unfolding in orbit. But behind all that, there’s something less glamorous yet just as critical: how the boards inside talk to each other.

That’s where the PC/104 connector comes in.

Why PC/104?

The PC/104 connector has been a de facto standard in CubeSats for years. It’s a compact, stackable 104-pin connector that lets you plug one subsystem board on top of another, like Lego bricks. This is incredibly practical when your satellite is only 10 × 10 × 10 cm in size and every cubic millimeter matters.

But PC/104 isn’t just about holding boards together. It also defines how power, data, and control signals are distributed across the stack. This makes it possible to swap boards, add payloads, and ensure that your On-Board Computer (OBC), Electrical Power System (EPS), and other modules can speak a common language.

Common Interfaces in CubeSat PC/104 Connectors

Even though each mission may tweak things, most CubeSat PC/104 connectors carry a familiar set of interfaces:

Power rails

+5 V, +3.3 V, ±12 V, and sometimes the direct battery voltage (V_BAT). These ensure that different modules can power up without each having to reinvent power regulation.Ground distribution

Multiple ground pins are spread throughout the connector to reduce noise, provide reliable return paths, and improve robustness.Serial communication buses

UART (simple, reliable, and common for subsystem communication)

I²C (ideal for multiple low-speed sensors and devices)

SPI (higher-speed data transfer, often used for payloads)

Or any other communication protocol that is mission-specific.

GPIO (General Purpose I/O)

Flexible pins that can be defined as needed: interrupts (INT), timers (TIM), analog inputs (ADC), or simple digital logic.Synchronization lines

Chip selects, interrupts, and timing signals that keep multiple subsystems working in step.

Together, these cover both the must-haves (power and comms) and the nice-to-haves (flexibility for payloads and experiments).

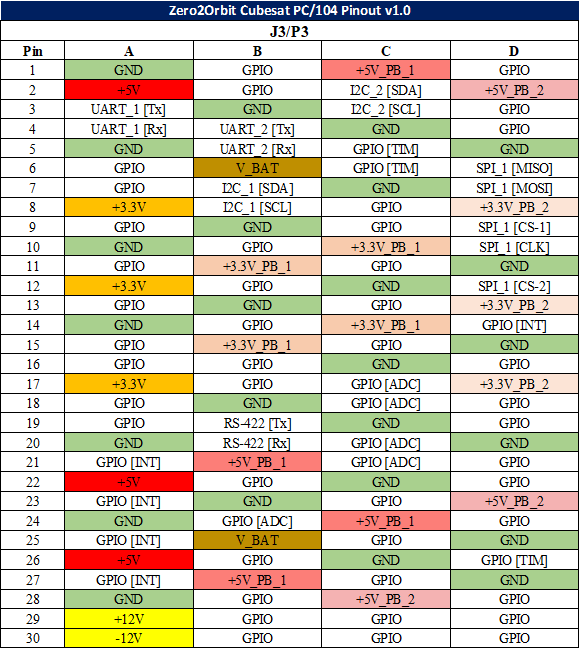

Our Take: Zero2Orbit CubeSat PC/104 Pinout v1.0

After analyzing the tradition, the trade-offs, and the needs of a learning kit, we’re excited to share the first version of our CubeSat PC/104 pinout.

This baseline aims to:

Provide all the common communication buses (UART, I²C, SPI, RS-422)

Include both direct and protected power rails (+5 V, +3.3 V, ±12 V, V_BAT)

Spread ground lines across the connector for integrity

Leave plenty of GPIOs available, some already defined for interrupts, timers, and ADC use

Here’s how it looks:

Why This Matters

This is just Version 1.0. We know that real missions — and real learners — will stress the connector in unexpected ways. Some will need more UARTs, others more ADC channels, and still others will want high-speed buses. That’s why we see this as a living standard, one that will evolve as we test it, get feedback, and adapt to new ideas.

But even at this stage, it gives us something precious: a shared backbone. A way for our learning kit to illustrate not just electronics in isolation, but the system-level thinking that real space engineering demands.

Because in the end, CubeSats are not about individual boards. They’re about systems that survive launch, work in orbit, and achieve their mission — and it all starts with the way they connect.

👉 Having said all that, this is the first version of the PC/104 pinout for our project. It’s the foundation for the learning kit we’re building, and we’re excited to see how it grows.